Why is the tool industry so important to the automotive industry?

For years, the automotive industry relies on the construction trend of "lightweight". Especially plastics are increasingly used. If you have, for example, previously used almost exclusively steel for the manufacture of fuel tanks, the automotive industry is investing these days in the fuel tanks made of plastic. The steel tanks only make a share of ca. 15 percent. Considering the advantages that bring the plastics processing with it, this is easily comprehensible.

Plastic parts, which are manufactured by the extrusion blow‑molding for the automobile industry, can be produced cheaper and faster. As for example, air channels in the car are made of thermoplastics and not of sheet metal. Apart from the lower cost of production, the customer also benefits from the usage of plastic products. Hereby the ease of processing and the resulting weight savings of fuel consumption can be reduced. It can thus be reduced by the ease of. Also in crash- and other quality tests, the lightweight products perform often better than their steel counterparts.

Why is Kremann and Esser is the right partner for the automotive industry?

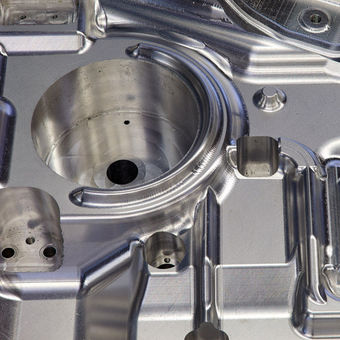

The tool‑and‑die maker Kremann and Esser has built up over decades a unique know‑how when it comes to the production of tools and devices for the automotive industry. With this expert status, Kremann and Esser is able to provide their support at the construction, according to the saying: "Won't work – is not possible".

As a technology leader, Kremann and Esser is the first contact when it comes to the manufacturing of products that have never been there before. However, even with well‑known products the customers from the automotive industry rely on the quality, efficiency and precision of Kremann and Esser. Many times it was the mold maker from Kierspe who offered his customers decisive advantage.