What is tool manufacturing?

Kremann and Esser is an established expert in the field of mold construction, a specialty of tool construction.

While at the beginning of the 90's there was a tool‑and‑die maker who produced any tool, companies today specialize in the various subjects of tool manufacturing. The mold construction is attributable to "the original form technology" in which a solid object is produced of a shapeless raw material, such as plastic or steel.

The range of products produced by this process is extremely diverse: fuel tanks, plastic packaging and children's toys are just some of the many product options.

Why should you trust Kremann und Esser at the tool manufacturing?

With a company history about more than 50 years, the toolanddie maker and system supplier Kremann and Esser has developed an expertise, seeking similar ones. Especially in the development of molds and tools for extrusion blow molding, the company from Kierspe is the first contact person for customers in the automotive, packaging, toys, and chemical industries.

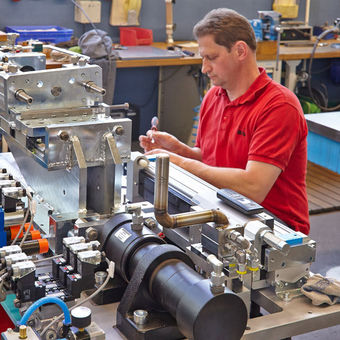

Kremann and Esser is characterized by exceptional precision, speed and reliability. These values are achieved by the seamless connection of the individual production areas.

Because Kremann and Esser sees itself not only as a mold maker, but as a system supplier who delievers molds, gadgets and handling systems from a one single source.

Principles

- System solutions: Kremann and Esser provides you with complete system solutions: from the construction to a tool and fixture construction.

- Profitability: with the expertise in the field of extrusion blow molding provides, Kremann and Esser is able to deliver products with breakthrough advantages in terms of material savings and cycle times.

- Delivery performance: due to the development and manufacturing of tools from a single source, Kremann and Esser guarantee not only the highest quality, but also strict adherence to delivery dates.

- Service: service partners, who are distributed around the globe, it creates Kremann and Esser change requests and maintenance work in the shortest time to realize.

How is the approach at Kremann and Esser?

From construction to service support you need only one contact: Kremann and Esser! This guarantees the consistently high quality, efficiency and precision.

The construction department, under the direction of experts, is responsible for the creation of various qualified, even more complex products and tool drawings. Kremann and Esser supports its customers in the realization and optimization of technical drawings, even if they still have no clear idea. For each project, special emphasis is placed on efficiency, cycle time and material savings!

Especially when customers are unsure if their idea is even possible, Kremann and Esser draw on their know‑how. Therefore, the motto of the tool maker is also: "What is possible is done, what appears impossible, will be solved creatively".

Subsequently the in‑house modelmaking manufactures highly precise molds of wood and molds models according to article drawings or samples; manufacture can also be made by CNC‑controlled machine‑tool.

The casting of our blow molds made of fine zinc Z 430 (including the copper pipe cooling) takes place in foundry; the capacity comprises casting weights from 5 to 10.000 kg.

The tool manufacturing is competent for the manufacturing of any type of blow molds and size, in a range of tools from 50ccm up to 10,000 liters. The focus of our production is on the tools for industrial parts, especially for the extrusion blow molding process. Variety of services and performance are demonstrated here daily:

- Zinc tools and copper pipe cooling, also available with drilled or milled cooling.

- Reinforcements of cutting edges by the use of steel (cooled appropriate).

- Production of steel tools (in each steel variety) and tools made of forged aluminum with drilled cooling.

Precision is our drive – from the construction department and the modelmaking to the foundry and the core of the operation: tool manufacturing.

Step by step on the way to the perfect blow mold tool: Whoever does not have all the advanced-equipped stations and can not guarantee their seamless cooperation has no place in a precision area such as this.