The optical metrology of the future

This is what optical metrology can already achieve today

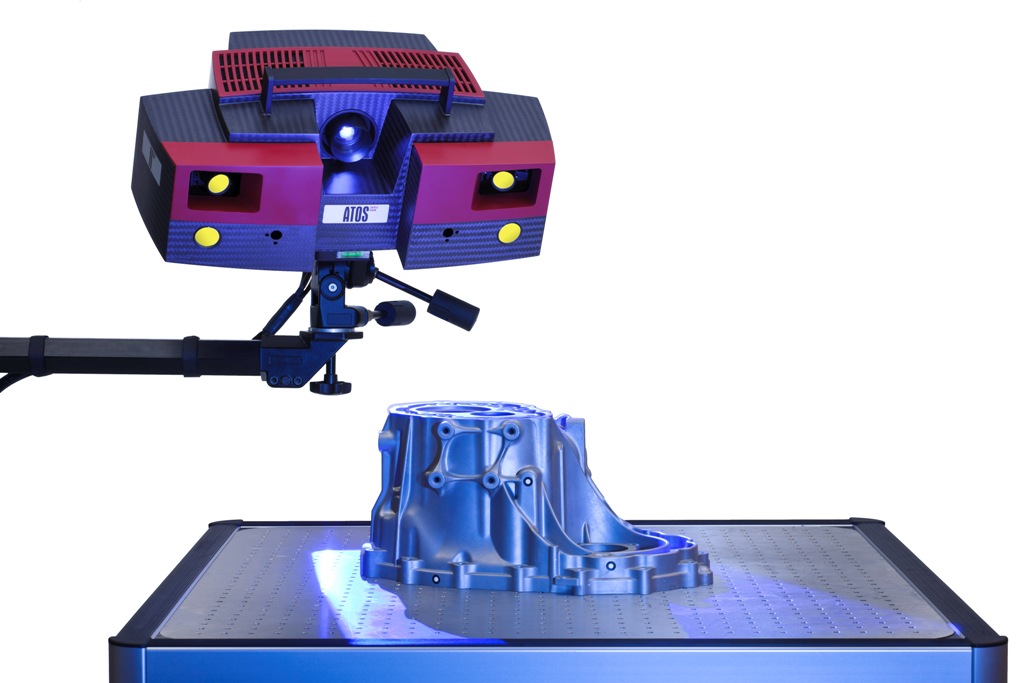

At this stage, optical metrology is already part of efficient quality management. We at Kremann and Esser use the ATOS software from GOM for the precise measurement of components. Within a very short time, data is available digitally and can be further processed in CAD, for example. Based on the existing models, new parts can be created that are even better and more accurate - exactly what your customers want. In addition, quality control is significantly simplified. Even the smallest inaccuracies are immediately noticeable thanks to the precise measurement. They can be easily eliminated, so that production becomes more efficient while maintaining the same high quality - ideal for your company.

Optical metrology with Augmented-Reality-Features

Augmented Reality is one of the trend topics in the industry. Augmented Reality combines digital information with real components. This takes quality assurance to a new level. This is because the model, which is created in CAD using optical measurement technology, can be placed over the video image of the corresponding component with the assistance of Augmented Reality features. This allows direct comparison and immediate documentation of the quality controls.

But that's not all: the advantages of Augmented Reality are also evident in the assembly of components. The right components can be identified on site and the exact position for the installation can be determined so that the assembly process is accelerated. The technology then helps to inspect the assembly without the need for paper documents.

Quality assurance trends

The goal of quality assurance is to avoid errors before they even occur. To achieve this, quality assurance will merge even more closely with production in the future. This way it will be possible to inspect components at the production site in real time and identify inaccuracies in the running process. By eliminating these as quickly as possible, errors are to be avoided and a production chain that is as straightforward as possible without interruptions is guaranteed. However, optical measurement technology with Augmented Reality features is not yet ready to be established across the board. On the one hand the technology has to be improved on the other hand the industry needs a certain amount of courage to open up to the modern possibilities of quality assurance.

Another trend is the shift from permanently installed terminals for measurement and testing towards mobile devices. This makes the controls more flexible, which facilitates the fusion of quality assurance and production. Of course, this also means that the measurement technology must be prepared for use at the production site and must deliver reliable results in different situations - always depending on the production site and the respective production step.

In addition, quality assurance will penetrate more and more areas. Customers' high demands on quality and individuality make it necessary to carry out quality controls down to the micro and nano levels. A continuous development of optical metrology and interfaces to other technologies is indispensable. We at Kremann and Esser always keep track with the latest developments in order to be able to offer our customers the best possible support.